What you'll learn

Service and Maintenance Course

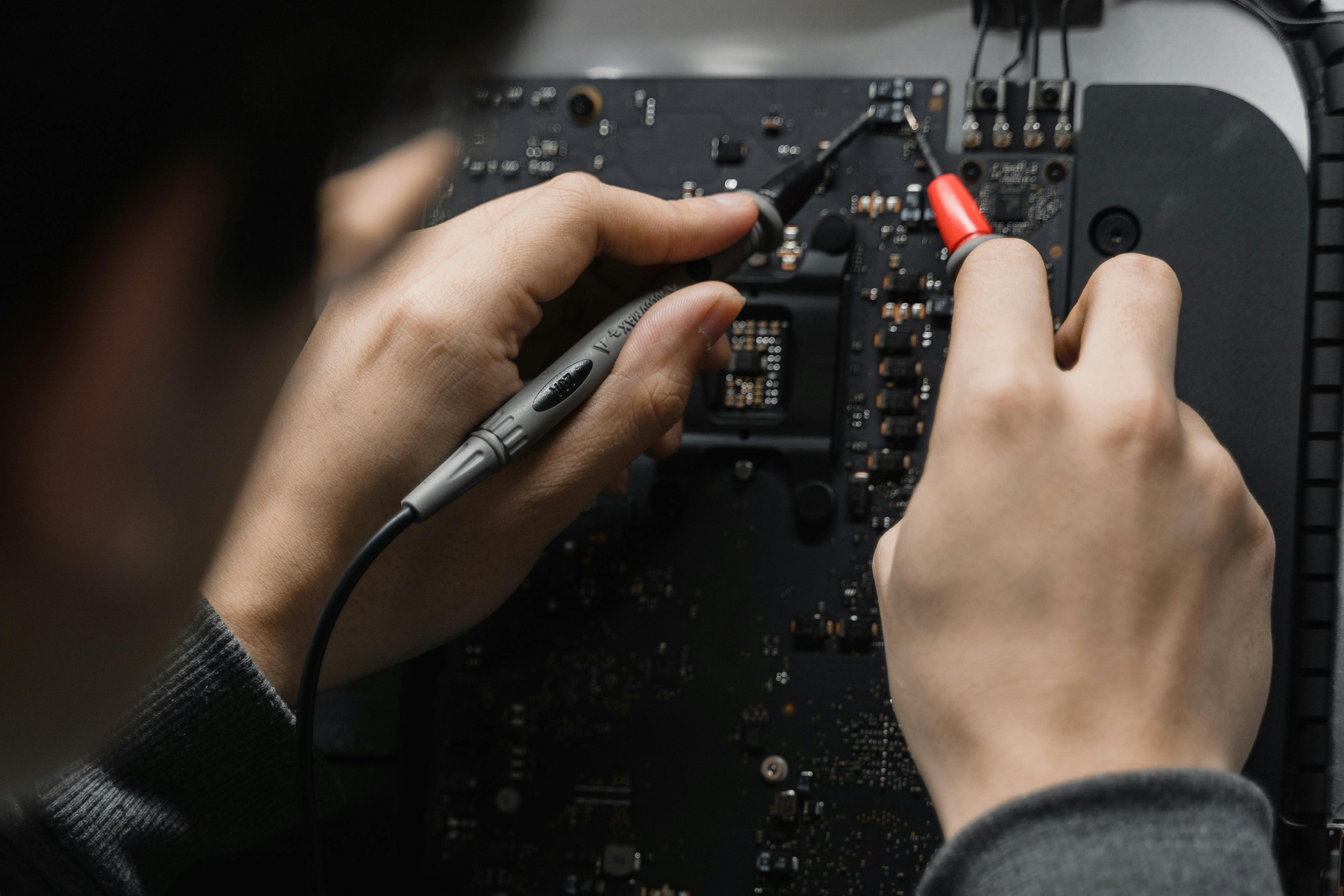

Overview

The Service and Maintenance module ensures the optimal performance, reliability, and longevity of equipment and systems through planned and efficient management. It tracks service schedules, maintenance activities, and equipment history to minimize downtime and enhance productivity. The module enables effective deployment of technicians, tools, and spare parts for timely service delivery. It supports both preventive and corrective maintenance operations, improving asset utilization and reducing operational costs. By providing real-time insights and reporting, it helps organizations maintain high service quality and customer satisfaction.

Course Objectives

- It helps to plan and automate routine maintenance activities to prevent equipment breakdowns and prolong asset life.

- It enables the recording, tracking, and resolution of customer service requests or internal maintenance tasks in an organized way.

- It Minimize unexpected equipment failures by ensuring timely maintenance, which keeps operations smooth.

- Document all maintenance activities accurately to track equipment performance and maintenance effectiveness.

- Optimize spare parts inventory to balance availability with carrying costs and avoid delays in repairs.

Course Content

Master Data Setup which includes the following:

- Product Master setup

- Customer Master setup

- Warehouse setup

- Service and Maintenance setup

- Resource setup

- Task Group setup

- Equipment setup

Process Flows Includes:

- Field Service Flow

- Plant Maintenance Flow

Widgets

Course content Collapse all

Free

This course include

- 8 Lectures

- Full lifetime access